WIRE DRAWING & CUTTING

Wire drawing is a manufacturing process used to reduce or change the diameter of a wire or rod by pulling the wire or rod through a single or series of drawing die(s). Processes used in wire drawing include wet and dry drawing. Methods used are single draft drawing and continuous drawing. Both process and method used depend on requirements of the finished product. During the wire drawing process, no material is shaved off, the wire simply gets longer. The material is cold-worked and hardens (and also increases in tensile strength) through each step.

Wire cutting is a process where the bright drawn materials are passed through a spinner where the wire is straightened and cut into specific requirement of the Customer

Wire and Wire Products supplies bright drawn coils & cut lengths made from CHQ, Ms, Alloy and Boron steel from SAE 1006 , SAE1008 , SAE 1015 , SAE 1018 , SAE 4140, EN 1A , 15B25 , EN8D ,10B21 ,S4SC.

COLD HEADING PROCESS

Wire and Wire is an ISO 9001:2015 certified manufacturer and supplier of carbon and alloy wire for a diverse customer base that includes the fastener, automotive, hand tools, appliance, off-road heavy equipment, construction, and other industries.

As the leader in cold heading quality wire, Wire and Wire can provide Spheroidized annealing, acid pickling, and wire drawing to suit your needs.

Our cleaning and coating facilities employ state-of-the-art acid pickling technology for high productivity with uniform coating characteristics (for lime, borax and zinc phosphate with reactive lube) and minimal statistical variability on the finished product.

You should expect nothing but the best from us in cold heading quality rod & wire. Republic’s continuous Spheroidized annealing furnaces provide uniform product to achieve higher levels of productivity.

GRADES : All types of Carbon Steels confirming to JIS G3532 ,ASTM A510M & BS 970 ,IS1673 ,IS4454.

PICKLING & PHOSPHATING

In our Phosphating Process during acid picklingstrength is maintained in such a way so that chemical reaction involves the evolution of hydrogen which tends to lift the scale from steel and not embedded in steel , Cleaning time vary considerably depending on acid strength so that all traces of acid trag-out from the pickled material. This rinsing may optionally be followed by a second rinse in warm water.Phosphating is done by way of immersion method where the parameters like Pointage ,Temperation& duration are well controlled to meet the specific requirement of our customers.

Wire and Wire Products undertakes phosphating of Round Steel Wires & Bars

HEAT TREATMENT SERVICES

STRESS RELEIVING

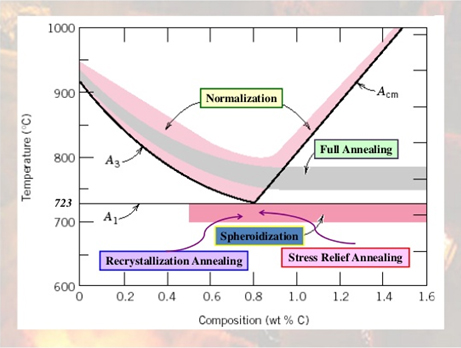

Steel materials , welded steel structures or cold formed parts tend to possess internal stresses caused mainly during their manufacture and uneven cooling. This internal stress causes brittleness at isolated locations in the steel materials, which can lead to sudden breakage or failure of the material. Stress relief annealing process is used to ensure there is reduced risk of distortion of the work piece during machining, welding, or further heat treatment cycles. This process involves heating the steel materials to a temperature of around 600 – 650 deg C. The temperature is maintained constantly for one to three hours and then the steel materials are allowed to cool down slowly in still air.

Stress Relieving( to reduce the residual stress formed during cold working) is done at Wire & Wire Products for all types of materials on Job Work basis as per the customer requirements.

ANNEALING

Annealing is a process of heat treatment that alters the properties of steel to increase its ductility and to make it more workable. It involves heating the steel to slightly above its critical temperature, soaking at that temperature for a time sufficient to allow the necessary changes to occur and then cooling at a predetermined rate .Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

Based on the Customers request all types of Annealing like Soft ( stress free material for further process like machinability , cold heading etc) , Normalizing(generally applied to enhance mechanical properties by refining the micro structure) is done at WIRE & WIRE PRODUCTS.

SPHEROIDIZE ANNEALING

Spheroidizing is a process of heating and cooling steel material that produces a rounded or globular form of carbide in a matrix of ferrite. Spheroidizing annealing process is used for those high carbon steels and alloy steels which are to be machined or cold formed in subsequent processes. The process improves the machinability of the steels by improving the internal structure of the steels. This can be done by three methods heating just below the lower critical temperature of about 700 – 750 deg C and the temperature is maintained for about 8 hours before the steel material is allowed to cool down slowly or heating and cooling of the steel material is done alternatively between temperatures just above and below the lower critical temperature and then the material is cooled slowly or which is for tool and alloy steels, the steel material is heated to a temperature around 750 – 800 deg C and held at that temperature for several hours before slow cooling.

Extra care has been taken at WIRE AND WIRE PRODUCTS to meet the requirements of Customers in all angles.